What products are involved in this article?

SRV Inline viscometer.

What is the purpose of this article?

To give an overview of the SRV inline viscometer with Ingold process connection, its uses, and installation options.

1. OverviewThe Ingold process connection is designed by Mettler Toledo and is used to provide a reliable and secure connection between a sensor or probe and the industrial process pipeline, tank or reactor. It is often used in industries like pharmaceuticals, food and beverage, chemical manufacturing, and water treatment.

2. Rheonics Inline Viscometer with Ingold Process ConnectionSRV probe configuration

SRV is a Rheonics sensor for inline viscosity measurement. Read more on SRV here.

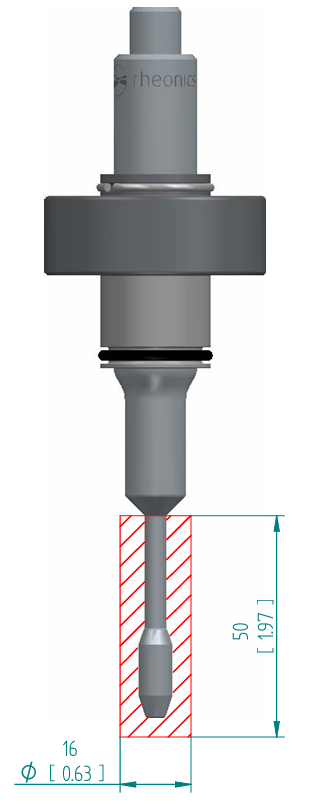

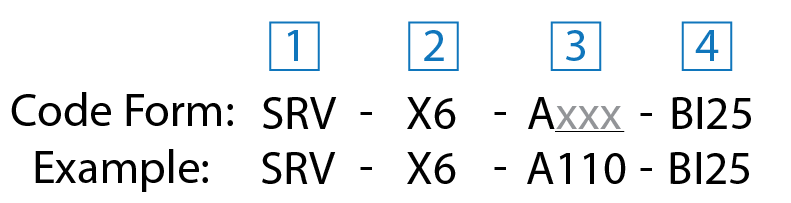

Rheonics offers the SRV-X6 slimline probe as a sensor probe variant compatible with Ingold connection size DN25. The probe, shown in Figure 1, is customizable in insertion length (A code) with minimum insertion of 110 mm, and supplied with a retaining ring and a nut as also shown in Figure 1. The probe order code is SRV-X6-Axxx-BI25, where Axxx indicates the length in milimeters; e.g., A110 means 110 mm insertion length.

Figure 1. SRV-X6-A110-BI25 - SRV Slimline with Ingold process connection

Installation requirements

Rheonics SRV has two installation requirements to ensure repeatable and reproducible readings while maintaining the configured accuracy.

Have the SRV sensing area (shown in red in Figure 2) always immersed in the fluid.

Avoid deposits and dead zones within the sensing area. Here, dead zones can be defined as any space where fluid volume is not representative of the fluid state at which it needs to be measured, e.g. stagnant areas in a flowing line.

Figure 2. Sensing area of SRV sensor probe

Rheonics SRV measures fluids in static and dynamic conditions up to approximately 10 m/s of fluid speed. It is also robust against air in fluid and external vibrations, thanks to the Rheonics patented BTR technology.

Installation port

For installation in tanks, reactors, or pipes, the SRV-X6-Axxx-BI25 requires:

- Proper socket selection: A G1 1/4 male threaded connection for the probe's nut.

- Adequate sealing: An O-Ring 20x2.5 mm (delivered by Rheonics in FKM).

- Correct probe insertion length: The probe should be ordered with the correct insertion legnth A, such that when installed in the socket, the sensing element is always wetted and away from dead zones during measurements.

As shown in Figure 1, the probe is delivered with the retaining ring, nut, and O-ring, thus only requiring the welded port (socket). Review the detailed dimensions of the SRV Ingold connection to make sure the proper socket connection and length are used for a smooth installation.

Suggested off-the-shelf sockets for installation are those offered by Mettler Toledo, such as the straight socket 40/DN25 or the titled or angled socket 40/DN25/sch 3.1.

3. How to orderSensor Probe Order Code for Rheonics SRV-X6 with Ingold DN25 | |||

| |||

| 1 | Rheonics SR- Type Sensor SRV: Inline Viscometer | 3 | Insertion Length "A" Distance from sensor connection to tip. Defined by client. |

| 2 | Probe Variant - X6 | 4 | Process Connection "B" BI25: Ingold DN25 process connection. |

The appropriate RFQ page for SRV viscometer should be used to configure other options of the sensor, like viscosity range, calibration accuracy, pressure rating, etc. | |||

Example:

SRV - Ingold Order Code | ||||

Description | Supplier | Order code | Drawing | 3D model |

Inline viscometer - SRV | Rheonics | SRV-X6-A110-BI25 | ||

4. Installation examplesThe versatility of Ingold connections allows for various installation points on a tank or reactor.Installations from reactor's wall or top are highly common and convenient because these allow for a self-draining orientation, thereby chances of deposits in the dead zones are minimize. Installation from reactor's bottom is particularly utilized in double-jacketed designs but require careful consideration as this position inherently poses challenges to effective cleaning and maintenance access.Next Figures illustrate the flexibility of the Ingold process connection used in the Rheonics SRV-X6 variant.

4.1 In reactor's wall and top:

SRV - Ingold Order Code | ||

Description | Supplier | Order code |

Inline viscometer - SRV | Rheonics | Side Installation: SRV-X6-A124-BI25 |

Top installation: SRV-X6-A414-BI25 | ||

Socket | Straight or Titled, G 1 1/4", DN25 | |

Figure 5. SRV-X6 Ingold installation in a tank

4.2 In double jacket tank:

SRV - Ingold Order Code | ||

Description | Supplier | Order code |

Inline viscometer - SRV | Rheonics | SRV-X6-A214-BI25 |

Socket | Straight or Titled, G 1 1/4", DN25 | |

Figure 6. SRV-X6 Ingold installation in a double jacket tank

Figure 6. SRV-X6 Ingold installation in a double jacket tank

4.3 In a glass reactor

SRV - Ingold Order Code | ||

Description | Supplier | Order code |

Inline viscometer - SRV | Rheonics | SRV-X6-A174-BI25 |

Socket | Straight or Titled G 1 1/4" DN25 | |

Figure 7. SRV-X6 Ingold installation in a Glass Reactor

Figure 7. SRV-X6 Ingold installation in a Glass Reactor

Resources[2] Ingold Mettler toledo catalog.

[3] Romynox Ingold DN25 adapter.

[4] Rheonics SRV sensor.

[5] Inline process density and viscosity meter SRD with Ingold connection - options and installation

DisclaimerPictures, photos, and images used are for illustration purposes and do not constitute any warranty or assertions on the suitability of use and should not be construed as an explicit or implicit recommendation or endorsement. All illustrations are given proper credit from our source of access and by their use here we do not specify or establish any copyright which belongs and stays unaffected with the existing copyright holder of that material.