What products are involved?

SRV - Inline Viscosity Meter

What is the purpose of this article?

To give an overview of the SRV NPT 3/4”-14 variant, installation guidelines, instructions, special considerations and available accessories.

1. IntroductionSRV is Rheonics sensor for inline viscosity measurement (viscometer). Read more on SRV here.

The NPT 3/4”-14 connection is Rheonics most commonly used design for SRV. In most cases, it is the most price-efficient option with the shortest lead time and the largest selection of accessories.

NPT threaded connections are very common in industrial applications. It is used both in low and high-pressure environments, up to 500 bar / 7500 psi. This type of connection allows for an easy process integration using some of Rheonics accessories or a thread in a pipe or vessel.

This threaded connection requires the use of a Teflon band. This helps to ensure a sealed connection and avoids cold welds (the process connection adaptor may get stuck with the sensor, leading to severe damage).

Figure 1: SRV NPT dimensions.

Figure 1: SRV NPT dimensions.

Specifications | |

Sensor | |

Order code | SRV-X1-34N |

Connection type | NPT |

Thread size | 3/4" |

Threads per inch (TPI) | 14 |

Wrench for installation | 32mm (1-1/4”) |

Drawing and CAD file | |

2. General installation guidelinesSR-sensors can be placed at any point in a process and at any orientation but is helpful to consider some terms that are usually involved in the sensor measurements.

2.1 Submersion

The SRV has a sensing element shown inside the red section in Figure 2. This section of the sensor should always be fully submerged in the fluid since SRV measures what is in contact with its sensing element. This can be a problem when in a process, the flow rate is low and the pipe isn’t usually full.

A possible solution is placing the sensor horizontally and parallel to the fluid (e.g. in an elbow) and not vertically and perpendicular. Also, the use of flow cell accessories can be considered, explained later in this article.

Figure 2: SRV sensing zone.

Figure 2: SRV sensing zone.

2.2 Stagnation/dead zone

Also related to the sensing zone of the sensor, the stagnations and dead zones are important to avoid. These are defined as any space, inside the red zone, where solids can accumulate and deposit, or where there isn’t fluid, but air or other unwanted materials that have negative effects on the measurement.

A clearance of at least 5mm is recommended between the sensor tip and a pipe wall or any other obstruction. In case this can’t be ensured, then in-situ calibration may be needed.

2.3 Orientation independence

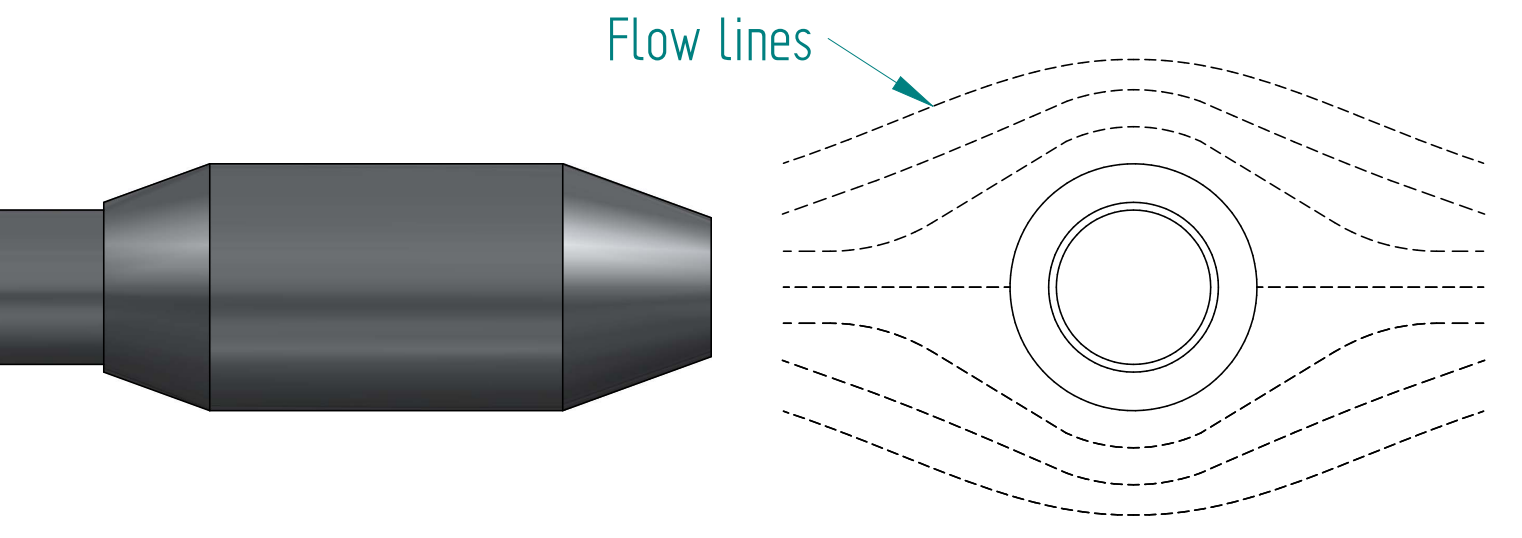

SRV has a symmetrical tip, making it possible to face a flowing fluid in any direction. Its shape enables the fluid to be in contact with the tip without creating recirculation zones.

Figure 3: SRV sensing tip.

Figure 3: SRV sensing tip.

2.4 Flow

For Newtonian fluids flow rate does not affect the viscosity, so SRV should measure the same values in static and moving states of a fluid. For non-Newtonian fluids, the flow rate does matter and viscosity readings may differ between static and moving conditions. For processes with non-constant flow rates, the recommendation is to install the SRV in a section in the pipeline with the most consistent flow rate to have a steady viscosity value.

Flow rate is also relevant to ensure the full submersion of the SRV sensing element into the fluid. For a process with a low flow rate, pipes may not be full of fluid at all points, so SRV should then be placed in a section where the pipe is usually full of fluid (i.e. after a pump). Installing the sensor upwards can solve the issue but should not be considered for fluids with solids or characteristics that can create deposits around the sensing element.

In all cases, the SRV’s sensing element should be submerged into the fluid. It’s best to avoid installations with long standpipes (i.e. using a long weldolet or tee), since that may lead to not good fluid transfer resulting in measurements that do not reflect the true state of fluid or worse high noise measurements.

Figure 4: Flow conditions in installation.

Figure 4: Flow conditions in installation.

2.5 Fluid type

The SRV in general works well with almost all fluids as long as the installation is correct. Some common fluid types and scenarios are mentioned next:

Static Newtonian fluids.

Moving Newtonian fluids regardless of flow rate changes (for non-Newtonian fluids viscosity changes with flow rate, but SRV ensures reproducibility at constant flow rates).

Bubbly fluids under moving conditions.

Important installation considerations are given in this article for these and other specific fluid types.

3. Installation common issuesAs explained above, for accurate, repeatable and reproducible readings of the SRV it is important to maintain the sensing element immersed and without stagnation zones that can lead to deposits around the sensing area.

Below some examples are listed where these concepts are not achieved leading to potential issues for the SRV.

3.1 Potential issues- NPT Tee connection

Potential issue explanation: A common mistake with installations of the SRV-X1-34N is using an off-the-shelf NPT Tee (Figure 5). An installation with the SRV, vertical or horizontally, mounted in such a Tee port, can be prone to stagnant and dead zones. Also, the SRV tip may pass through the tee and can be exposed to uneven inner walls that can create changes in the fluid’s flow lines (increasing turbulence) as in Figure 6.

Figure 5: Standard NPT Tee [6]

Figure 5: Standard NPT Tee [6]

Figure 6: Installation in standard NPT Tee with potential issues

Recommendation: In these cases, the Rheonics IFC-34N-SRV is recommended to ensure the flow surrounds the sensing element properly and stagnant zones are removed as in Figure 7.

Figure 7: Correct installation in Rheonics NPT flow cell

Figure 7: Correct installation in Rheonics NPT flow cell

3.2 Potential issues - NPT connection adapter

Potential issue explanation: At times, users may want to adapt the 3/4” NPT connection of the SRV-X1 to a different flange, like Tri-Clamp. They would use an adapter similar to the one shown in Figure 8. These adapters can lead to both incomplete immersion and stagnation zones prone to fouling or deposits at the base of the sensing element which will affect the measurements (see Figure 9). This scenario may not affect applications for low-viscosity fluids like ink but could be a significant problem for high-viscosity fluids like dough, adhesives, glue, and others.

Figure 8: Standard NPT to Tri-Clamp adapter [7]

Recommendation: The client should order the SRV with the required process connection to directly mount it inline without the need for additional adapters (Figure 9, installation to the right). If Tri-Clamp is required visit the SRV-X3. If custom flanges are required visit the SRV-X2.

Figure 9: Installation recommendation with NPT adapters

4. Process connection installation instructions4.1 Connection steps

i. Wrap a sealing compound (e.g. Teflon tape) around the sensor NPT thread 1.5 to 3 times in a clockwise direction, to ensure a leak-free seal.

ii. Place the sensor in the female threaded accessory.

iii. Turn by hand the sensor NPT thread until hand tightened.

iv. Use a wrench (32mm size or 1-1/4") to give the sensor from 1 up to 3 more full turns.

In total, according to ASME Standards, at least 3.5 and at maximum 6 full turns need to be ensured for a correct NPT installation. The sensor shouldn't be completely tightened.

3.2 Specific Process Connection installation instructions

In line: Ensure the sensing element is exposed to fluid, and avoid stagnation and dead zones. Consider placing the sensor upwards or parallel to the fluid for small flow rates that can’t fully surround the sensing element.

In tank: Place the sensor at the bottom, wall or lid of the tank as long as the sensing element can be fully submerged in the fluid and dead zones are avoided. Usually, it is useful if the sensor is placed at a tank’s height that has always fluid. Rheonics TMA-34N accessory is a tank mount adapter used for NPT SR-sensors, that should be considered in tank installations. This is detailed sections below.

Others - Thread flange: SRV NPT sensor can be mounted on a flange thread of the same size (3/4"-14). The flange needs to have an inner diameter larger than 26mm on the process side, the material should be either 304 or 316L and the height can't exceed 25mm. If the flange has a bigger height, an FPC-type (long insertion) sensor is needed.

Once again, in these and any installation cases, stagnation zones around the sensing element should be avoided. For thread flanges, the height of the standpipe of the connection is relevant as shown in the next figures.

5. Accessories available5.1 Weldolets

a. WOL-34NS

Weldolet for 2” pipes that ensures maximum exposition of the sensing element to the fluid. Also suitable for SRD NPT 3/4” -14. Refer to the WOL-34NS page for more information.

Figure 11: WOL-34NS.

b. WOL-34NL

Weldolet for 2.5” and larger pipes, also suitable for tank installations, that ensures maximum exposition of the sensing element to the fluid. Also suitable for SRD NPT 3/4” -14. Refer to the WOL-34NL page for more information.

Figure 12: WOL-34NL.

5.2 Flow cells

a. HPT-SRV

Suitable only for SRV NPT 3/4”-14 and recommended for lines with a small nominal diameter (around DN3 or 1/8”) and high pressures (up to 500 bar, 7500 PSI). Connecting threads for this accessory are 9/16-18 UNF.

Read more about this on its accessory page.

Figure 13: Flow cell HPT-SRV.

Figure 13: Flow cell HPT-SRV.

b. IFC-34N-SRV

Suitable only for SRV NPT 3/4”-14 and recommended for inline installation with nominal diameters of DN5 to DN25. Connecting threads for this accessory are NPT 3/4” -14.

For a diameter larger than DN25 (1”), we recommend using a bypass. Then, the flow cell can be connected via flexible hoses or fixed piping. Installing the sensor in a bypass is a common solution for process lines that require intense cleaning through means of pigging.

Read more about this on its accessory page

Figure 14: IFC-34N-SRV.

5.3 Tank mount adapter - TMA-34N

Suitable for SRV and SRD only in its NPT 3/4"-14 variant, this accessory is recommended for open vessels or tanks with a lid. It is composed of a small cell, wherein the sensor is installed, and a 3/4" pipe fixed at the top and with a variable length so the sensor can go as far as needed.

Read more about this on its accessory page or its support article here.

Figure 15: TMA-34N.

References[1]: https://rheonics.com/products/inline-viscometer-srv/

[2]: https://rheonics.com/product-accessories/

[3]: https://rheonics.com/product-accessories/wol-34ns/

[4]: https://rheonics.com/product-accessories/wol-34nl-accessory-page/

[5]: https://www.asme.org/codes-standards/find-codes-standards/b1-20-1-pipe-threads-general-purpose-inch

[6]: https://www.mcmaster.com/products/tees/low-pressure-stainless-steel-threaded-pipe-fittings-9/