What products are involved?

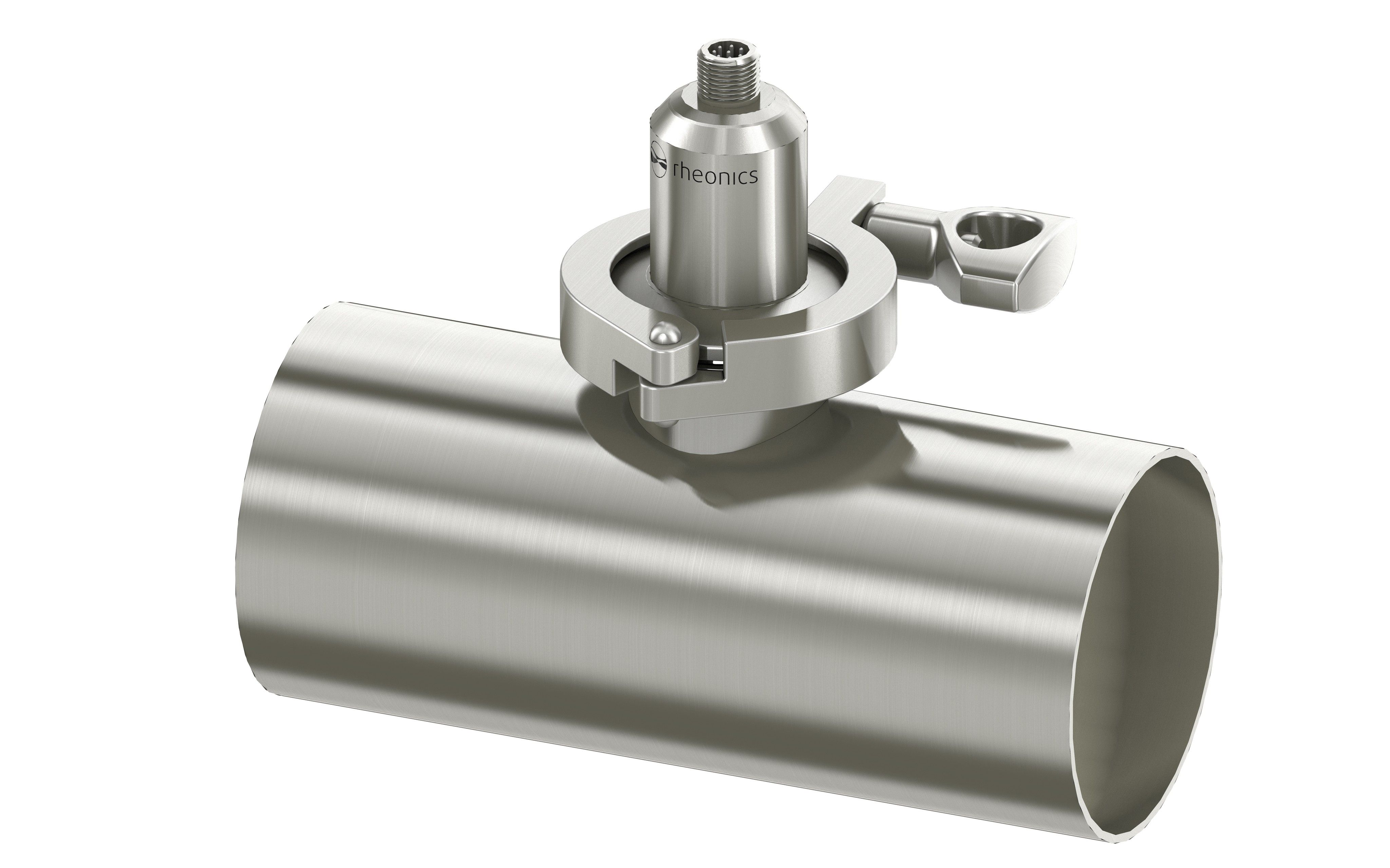

SRV - Inline Viscosity Meter

What is the purpose of this article?

To give an overview of the SRV with Tri-Clamp connection (SRV-X3), installation guidelines, instructions, special considerations and available accessories. Tri-Clamp connection varies in size but this article is valid for all of them.

1. IntroductionSRV is Rheonics sensor for inline viscosity measurement (viscometer). Read more on SRV here.

At Rheonics, the SRV with Tri-Clamp connections is typically on stock in different sizes. For some high sizes, less stock is available, so the lead-time for delivery can increase.

See all Tri-Clamp sizes available for Rheonics SRV inline viscometer.

See all CAD models for Rheonics SRV inline viscometer with Tri-Clamp connection.

A Tri-Clamp (TC) fitting allows for an easy process installation in pipes and tanks. It is also widely used in the food industry, and at any place where frequent cleaning and disassembly are required. A Tri-Clamp connection is composed of 3 main parts: the ferrules, a gasket and a clamp. Find out how to select the correct gasket here. Pressure and temperature ratings vary for a Tri-Clamp connection, based on the type of clamp used.

Rheonics offers the SRV-HS-X3 as hygienic viscometer with 3-A and EHEDG certificates available.

Figure 1: Dimensions of Standard and Hygienic SRV-X3 version.

Figure 1: Dimensions of Standard and Hygienic SRV-X3 version.

Specifications | |

Sensor | |

Order code | SRV-X3 |

Connection type | Tri-Clamp (TC) |

Sizes available | From DN25/30/40 - 1.5" - OD50.5 up* |

CAD file | |

*Smaller Tri-Clamp connections are available for flush sensor versions.

Check if your required Tri-Clamp norm and size meets the requirements for Rheonics SRV here.

Find CAD files for various TC sizes here.

2. General Installation Guidelines

SR-sensors can be placed at any point in a process and at any orientation but is helpful to consider some terms that are usually involved in the sensor measurements.

2.1 Submersion

The viscometer SRV has a sensing element shown inside the red section in Figure 2. This section of the sensor probe should always be fully submerged in the fluid since SRV measures what is in contact with its sensing element. Incomplete submersion can lead to innacurate or systematic errors in viscosity readings. This is a common issue with unfill pipes due to very low flow rate.

When there is a chance of incomplete pipe filling then consider installing the sensor in a flow cell or assembly which would ensure the section around the sensing element is full before fluid exits. This can be done by making the outlet higher than the inlet (Figure 3a and 3b). However here consideration should be given to create self-draining installs that minimizes the chances of sedimentation.

Figure 2: SRV sensing area.

Figure 3a shows an installation with the SRV in the IFC-15T-34N-SRV flow cell, inlet and outlet ports are 3/4” NPT threads.

Figure 3b shows an equivalent alternative with the FET-15T flow elbow tee from Rheonics which has a shorten 1.5” port for the SRV, also available in 2” size.

Both solutions have the inlet below the outlet port to favor the complete immersion of the sensing element in the fluid before it exits the cell.

Figure 3a: SRV mounted in IFC-15T flow cell

Figure 3b: Flow cell to ensure full immersion of sensor.

2.2 Stagnation/dead zone

It is not a good practice to have dead or stagnations zones around the sensing area (Figure 3). A stagnation or dead zone is where a fluid transfer is not good and older fluid may not be fully displaced by newer fluid. This leads to incorrect measurements due to part or all of the measurement being influenced by stationary fluid that is no longer representative of the actual process fluid.

Consider that some ferrules may cause dead zones in the gaps created with installation. Rheonics recommends the use of short ferrules or its WFT-15T ferrule weldolet that eliminates possible dead zones for the SRV and SRD standard sensors.

A clearance of at least 5mm is recommended between the sensor tip and a pipe wall or any other obstruction.

2.3 Orientation independence

SRV has a symmetrical tip, making it possible to face a flowing fluid in any direction. Its shape enables the fluid to be in contact with the tip without creating recirculation zones.

Figure 4: SRV sensing tip.

2.4 Flow

For Newtonian fluids flow rate does not affect the viscosity, so SRV should measure the same values in static and moving states of a fluid. For non-Newtonian fluids, the flow rate does matter and viscosity readings may differ between static and moving conditions. The recommendation for processes with non-constant flow rates is to install the SRV in a section in the pipeline with the most consistent flow rate to have a steady viscosity value.

Flow rate is also relevant to ensure the full submersion of the SRV sensing element into the fluid. For a process with a low flow rate, pipes may not be full of fluid at all points, so SRV should then be placed in a section where the pipe is usually full of fluid (i.e. after a pump) or consider the use of a flow cell.

In all cases, the SRV’s sensing element should be submerged in the fluid. It’s best to avoid installations with long standpipes (i.e. using long ferrules or a long elbow tee), since that may lead to a bad fluid transfer resulting in measurements that do not reflect the true state of fluid or worse high noise measurements.

When installing in a standpipe, choose the appropriate insertion length of the sensor by selecting long insertion probes. This allows the sensing element to clear the stagnation zone and be in the fluid that is of interest for measurement, as in the next figure.

Figure 5: Long insertion probes for long standpipes.

3. Process Connection installation instruction3.1 Connection steps

A Tri-Clamp connection requires two ferrules or flanges, a seal and a clamp, as in the next figure. Remember that, a short ferrule port (e.g. Rheonics WFT-15T) is needed to avoid dead zones around the sensing element.

Figure 6: Tri-Clamp connection components.

The general steps for a Tri-Clamp connection are:

i. Have a welded ferrule in the pipe or tank.

ii. Place the gasket properly into the seat of the ferrule.

iii. Place the sensor Tri-Clamp connection on the gasket and verify it is correctly aligned.

iv. Loosen the clamp so it can fit around the ferrule.

v. Place the clamp, verify ferrules are within the clamp’s groove.

vi. Start tightening the clamp until a leak-proof connection is made.

Be careful not to over-tighten the clamp, this can damage the gasket and ferrules.

3.2 Specific Process Connection installation instructions

- In line: For inline installations consider the sensing area (Figure 3) and a minimum clearance of the sensor tip to the pipe inner wall (5 mm). A perpendicular Tri-Clamp installation of the SRV is not possible for most 1”, 1.5” or 2” pipes (for 2” it depends on the pipe norm). In those cases, the installation is recommended to be parallel or with a flow cell, check accessories FET-15T-XXX and IFC-15T-SRV. For bigger lines the sensor can be mounted perpendicular to the flow, Rheonics recommends the WFT-15T ferrule for such cases.

- In tank: Place the sensor at the bottom, wall or lid of the tank as long as the sensing element can be fully submerged in the fluid and dead zones are avoided. The WFT-15T ferrule is recommended for these installations. Usually, it is useful if the sensor is placed at a tank’s height that has always fluid. If there is a hygienic requirement, the SRV TC can be ordered with a hygienic design, the SRV-HS-X3 as in Figure 1 (optional 3-A and EHEDG certification) and should be mounted with a hygienic adapter (e.g. flush welding flange like ISO 1127).

- Others: Larger pipelines or tanks often need a longer probe (i.e. jacketed tanks or pipes), in those scenarios, the client should use a long insertion probe (FPC sensors) - Order code: SRV-X5.

Figure 7: SRV installation in line.

Important: Avoid using adapters to install the SRV in a Tri-Clamp port when the probe has a different process connection e.g. threaded. This is the case for NPT to Tri-Clamp adapters, as showm in Figure 8. Rheonics SRV should be ordered with the correct process connection to directly mount it inline without the need for additional adapters that can affect the correct immersion of the sensing element.

4. Accessories available4.1 Weldolet - WFT-15T

Weldolet for 1.5” Tri-Clamp sensor connection that ensures maximum submersion of the sensing element. Suitable for the SRV and SRD X3 1.5”. It can be used for process integration into Process lines, mixing vessels, reactors, etc. Read more about this on its accessories page.

Figure 9: WFT-15T ferrule

4.2 Flow cells

a. IFC-15T-SRV

Inline adapter for 1.5” Tri-Clamp sensor with 3/4” NPT inlet and outlet ports. This accessory is recommended for DN5 up to DN25 pipes, ensuring optimal flow over the sensing element and minimal stagnation zones. Read more about this on its accessories page.

Figure 10: IFC-15T-SRV

b. FET-15T-XXX

Tri-Clamp elbow tee for 1.5” Tri-Clamp sensor with welding inlet and outlet ports of 1.5” size. Also available for other line sizes on request. Review its web accessory here.

Figure 11: FET-15T-XXX

c. FET-15T-15T

Tri-Clamp elbow tee for 1.5” Tri-Clamp sensor (DN25/32/40) DIN11850 with same connection for inlet and outlet ports. Also available for other port sizes under request. Review its accessory page here.

Figure 12: FET-15T-15T

d. FTP-15T-XXX

Tri-Clamp tee spool piece for perpendicular installation of the SRV with Tri-Clamp 1.5” process connection. Only available with welding inlet and outlet ports of 2", 3”, 4” or 6” size. Review its accessory page here.

Figure 13: FTP-15T-XXX

References[1]: https://rheonics.com/products/inline-viscometer-srv/

[2]: https://rheonics.com/product-accessories/ifc-15t/